Activated carbon is one of the most effective and affordable air purification technologies available. It removes odors, gases, and volatile organic compounds that other filters miss entirely.

But here’s what manufacturers don’t advertise: carbon filters stop working long before their suggested replacement date, and we’ll show you how to tell when yours is actually saturated.

What Is Activated Carbon

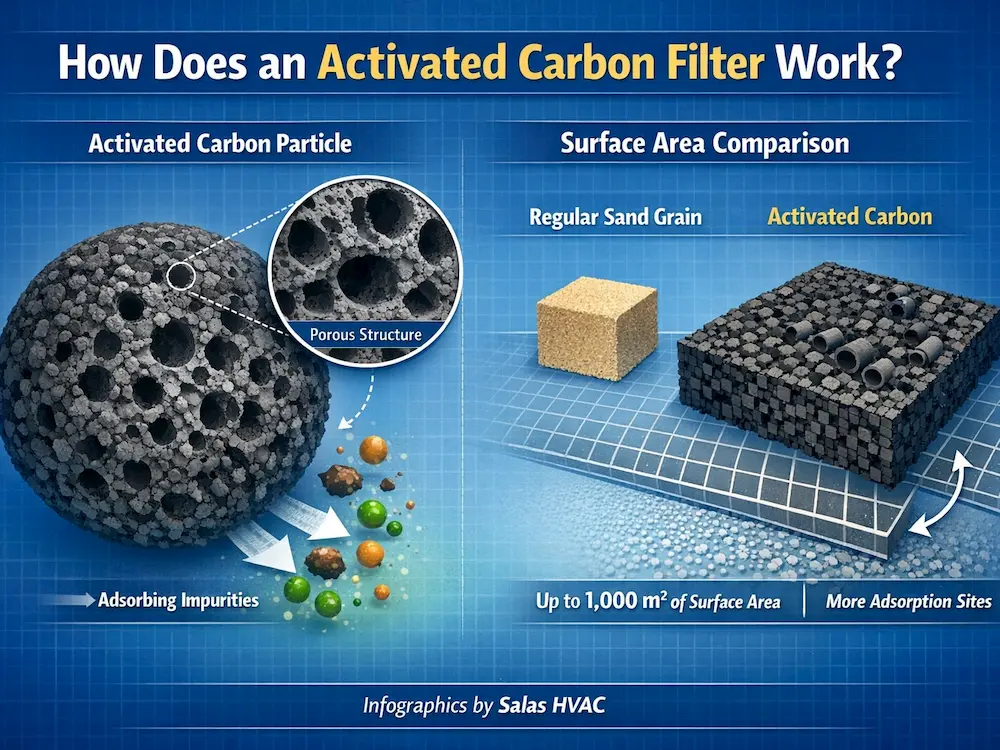

Activated carbon is charcoal treated with oxygen to open millions of microscopic pores. The process creates exceptionally porous material with enormous surface area for its weight.

One gram of activated carbon provides over 3,000 square meters of surface area. For perspective, a teaspoon of activated carbon offers more surface area than a football field.

Manufacturers create activated carbon from various organic materials including coconut shells, wood, coal, petroleum coke, and peat.

The source material and activation method determine the filter’s effectiveness for specific contaminants.

The Activation Process

Raw carbon materials become activated through heat or chemical treatment. The most common method uses high-temperature steam between 600-900 degrees Celsius.

This process creates a dense network of microscopic pores varying in type and size. Each presents different adsorption characteristics. The pores range from small micropores to larger macropores.

Chemical activation uses phosphoric acid, zinc chloride, or potassium hydroxide at lower temperatures. This method produces carbon with specific pore structures tailored to target particular contaminants.

The activation process determines the carbon’s chemical properties. These properties make the filter attractive to various pollutants. Different methods yield activated carbon optimized for different applications.

Adsorption vs Absorption

Understanding the difference between adsorption and absorption explains how activated carbon filters function.

Absorption occurs when one substance enters the volume or bulk of another substance. Think of a sponge soaking up water. The liquid penetrates throughout the sponge’s structure.

Adsorption happens when molecules adhere to a surface. Pollutants stick to the outside of carbon particles rather than being absorbed into them.

This distinction matters for filter performance. Adsorption allows activated carbon to capture gaseous pollutants that pass through the filter.

The massive surface area created by millions of pores provides countless spots where contaminant molecules can stick.

How the Adsorption Process Works

When contaminated air passes through an activated carbon filter, pollutant molecules encounter the carbon’s porous surface. If conditions are right, these molecules adhere to the carbon and get trapped.

The process relies on molecular attraction. Activated carbon and many organic pollutants share similar molecular structures. This similarity creates natural attraction between the carbon and contaminants.

Picture pollutants as moths drawn to a flame. They seek out activated carbon and land on its surface where they become trapped. Clean air then exits the filter.

Physical Adsorption

Physical adsorption occurs through weak van der Waals forces. These intermolecular forces create attraction between the carbon surface and pollutant molecules without chemical bonding.

The process is reversible under certain conditions. Temperature increases can release adsorbed molecules. This explains why carbon filters lose effectiveness in high-heat environments.

Chemisorption

Chemisorption involves actual chemical reactions between the carbon surface and contaminant molecules. These bonds are stronger than physical adsorption.

Chemical properties of the carbon surface interact with specific pollutants. Electrical forces between activated carbon and certain contaminants result in ion exchange or stronger adsorption.

What Activated Carbon Removes

Activated carbon excels at removing volatile organic compounds. The Environmental Protection Agency identified more than 225 chemicals that activated carbon filtration effectively removes.

Common contaminants removed:

- Benzene

- Formaldehyde

- Acetone

- Toluene

- Chloroform

- Nitrogen dioxide

- Methane

- Radon

- Cannabis terpenes

- Cooking odors

- Pet odors

- Smoke compounds

- Industrial fumes

Studies show VOC levels can be reduced by up to 80% when using activated carbon air filters.

What Activated Carbon Doesn’t Remove

Carbon filters have limitations.

- They don’t capture particulate matter like dust, pollen, or pet dander. That’s why air purifiers combine HEPA filters with activated carbon.

- Carbon doesn’t adsorb carbon monoxide effectively. This gas poses particular danger because humans can’t detect it. Spaces requiring carbon monoxide protection need dedicated CO detectors and removal systems.

- Activated carbon doesn’t kill bacteria or remove viruses. Microorganisms pass right through carbon filters. HEPA filtration or UV light handles biological contaminants.

- Certain low molecular weight gases resist carbon adsorption. Hydrogen sulfide, ammonia, and chlorine in vapor phase need specially treated carbon or alternative removal methods.

Factors Affecting Carbon Filter Performance

Surface Area and Pore Structure

Greater surface area provides more adsorption sites. The best filtration occurs when carbon pores are barely large enough to accommodate target contaminants.

Pore size distribution impacts which pollutants get captured.

- Micropores (less than 2 nanometers) handle small molecules.

- Mesopores (2-50 nanometers) capture medium-sized molecules.

- Macropores (greater than 50 nanometers) allow larger molecules to access smaller internal pores.

Contact Time

Longer exposure between air and carbon increases removal efficiency. Slower airflow allows more time for adsorption to occur.

This explains why thicker carbon beds perform better than thin layers.

More carbon means longer contact time as air travels through the filter. Empty bed contact time (EBCT) measures this crucial variable.

Temperature and Humidity

Lower temperatures generally improve adsorption. Cold conditions help pollutant molecules stick to carbon surfaces.

High humidity reduces effectiveness. Water molecules compete for adsorption sites on the carbon surface.

Above 70% relative humidity, performance decreases as water starts occupying active sites.

Concentration Levels

Activated carbon works best at removing high molecular weight compounds with low solubility. The carbon’s molecular structure creates stronger attraction to similar molecules.

Contaminant concentration affects filter lifespan. Higher pollutant levels saturate carbon faster. Lower concentrations allow longer filter life but may require more contact time for effective removal.

Competitive Adsorption

When multiple contaminants exist in air, they compete for adsorption sites. Strongly adsorbed compounds attach to carbon in greater quantities than weakly adsorbed ones.

This can cause less-adsorbed pollutants to leave the filter while better-adsorbed ones continue being removed. Understanding competitive adsorption helps predict filter performance in real-world conditions.

Types of Activated Carbon Filters

Granular Activated Carbon

GAC uses larger carbon particles compared to powdered forms. The relatively larger particle size presents smaller external surface area but allows easier airflow.

Granular carbon suits gas and vapor adsorption because these substances diffuse rapidly throughout the filter. Most residential air purifiers use GAC for odor and VOC removal.

Powdered Activated Carbon

PAC consists of crushed carbon particles. About 95-100% passes through a designated mesh sieve. The finer material provides more external surface area per unit volume.

Powdered carbon works well when added directly to other processes. Industrial applications inject PAC into airstreams, then filter it out downstream. This method handles high flow rates with lower concentrations.

Carbon Cloth

Technical rayon fiber processed into activated carbon cloth provides unique filtration properties. The cloth form factors work well in specialized applications requiring flexible filter media.

Applications in Air Purification

Residential Air Cleaners

Home air purifiers combine HEPA and activated carbon filters. HEPA captures particles while carbon handles gaseous pollutants and odors. This combination addresses both major indoor air quality concerns.

People use carbon filters to remove cooking smells, pet odors, smoke, and VOCs from building materials.

HVAC Systems

Whole-house air cleaners integrate carbon filters into HVAC systems. These units filter all air circulating through ductwork. Maintaining proper filter replacement schedules keeps systems running efficiently.

Carbon filters in HVAC applications face higher airflow rates. Thicker carbon beds compensate for reduced contact time.

Industrial and Laboratory Settings

Laboratories use activated carbon to protect workers from chemical fumes. Ductless fume hoods rely on carbon filters to clean contaminated air before releasing it into rooms.

Industrial facilities employ carbon adsorption to control emissions, remove odors, and recover solvents. Large-scale activated carbon beds handle substantial air volumes.

Filter Saturation and Replacement

All activated carbon filters eventually reach capacity. When adsorption sites become full, the filter stops removing contaminants. Some pollutants may even release back into the air.

This phenomenon is called breakthrough. The contaminant “breaks through” the filter into treated air. In extreme cases, contaminant concentration in filtered air exceeds untreated air levels.

Signs Your Carbon Filter Needs Replacement

- Odors return that were previously controlled

- Air quality seems worse despite filter operation

- Allergic reactions or respiratory symptoms increase

- Visible discoloration of filter media

- Manufacturer’s recommended replacement interval reached

Replacement Guidelines

Replace carbon filters based on usage and environment. Heavy odor exposure or high VOC levels saturate filters faster. Manufacturers provide estimated lifespans assuming average conditions.

- Cooking odors may require changes every 6-12 months.

- For cannabis smoke removal, replace filters every 3-6 months.

- Light residential use extends lifespan to 12-18 months.

Never exceed manufacturer recommendations. Saturated carbon loses effectiveness and can’t protect air quality. We recommend tracking air quality changes rather than relying solely on time intervals.

Activated Carbon in Water Filtration

The same adsorption principles apply to water treatment. Contaminants in water adhere to carbon surfaces or become trapped in pores as water flows through.

Water filtration faces unique challenges. Different contaminants in liquid versus gas phase behave differently. Water temperature and pH affect adsorption rates. Lower temperatures and pH levels typically improve performance.

Carbon water filters excel at removing chlorine, taste and odor compounds, and organic chemicals. They help eliminate trihalomethanes (THMs) created during water disinfection. Some systems reduce lead, though additional filter media often combines with carbon for heavy metal removal.

Reactivation and Regeneration

Saturated activated carbon can be regenerated through thermal treatment. High temperatures drive off adsorbed contaminants, restoring adsorption capacity.

Manufacturers collect used carbon filters and regenerate them in specialized facilities. The process heats carbon to 800-900 degrees Celsius in controlled atmospheres. This burns off organic contaminants while preserving the carbon structure.

Regenerated carbon maintains 85-95% of original adsorption capacity. Some performance decrease occurs from pore structure changes, but regeneration proves more economical than producing new carbon.

Home users typically replace filters rather than regenerate them. The equipment and expertise required make professional regeneration more practical.

Cost Effectiveness

Activated carbon filters cost $15-100 for residential units. Lifespan ranges from 6-18 months depending on usage. Commercial systems require larger investments but handle higher volumes.

When calculating filter costs, consider adsorption capacity rather than just purchase price. High-capacity carbon removes more contaminants per gram, extending replacement intervals.

Quality matters more than quantity. Inferior carbon with poor pore structure won’t perform regardless of how much you use. Purchasing from reputable manufacturers ensures proper activation and testing.

Combining Filtration Technologies

Activated carbon works best alongside complementary technologies. Multi-stage filtration addresses the full spectrum of air quality concerns.

Typical residential air purifier stages:

- Pre-filter: Captures large particles like hair and dust

- HEPA filter: Removes fine particles, allergens, bacteria

- Activated carbon: Adsorbs gases, VOCs, odors

- Optional ionizer or UV light: Additional germicidal protection

This layered approach extends carbon filter life. Pre-filters prevent particulate clogging.

HEPA handles what carbon can’t. Carbon eliminates what HEPA misses.

Testing and Standards

Iodine Number

The iodine number measures activated carbon’s capacity to remove organic compounds. This metric indicates the amount of iodine in milligrams, adsorbed by one gram of carbon under set conditions.

Higher iodine numbers generally indicate greater adsorptive capacity.

Quality activated carbon for air purification should exceed 900-1000 mg/g iodine number.

Butane Working Capacity

This test measures carbon’s ability to adsorb butane from air. Results correlate with real-world VOC removal performance. Butane working capacity indicates how much contamination the carbon can handle before breakthrough occurs.

CTC Value

The carbon tetrachloride test evaluates adsorption capacity for organic vapors. Higher CTC values indicate better gas-phase adsorption. This metric helps compare different activated carbon products for air filtration applications.

FAQs

How long do activated carbon filters last?

Lifespan depends on pollutant levels and usage. Light residential use provides 12-18 months. Heavy odor environments like kitchens or smoking areas need replacement every 3-6 months. High VOC exposure shortens lifespan.

Does activated carbon remove viruses?

No, activated carbon doesn’t capture or kill viruses. Viruses are biological particles that pass through carbon filters. HEPA filters capture particles 0.3 micrometers and larger, including most viruses and bacteria. UV light systems kill microorganisms. Use HEPA filtration or UV for biological contaminants.

Can activated carbon remove formaldehyde?

Yes, activated carbon effectively removes formaldehyde from air. Formaldehyde is a volatile organic compound that readily adsorbs onto carbon surfaces. Studies show activated carbon reduces VOC levels including formaldehyde by up to 80%. Replace filters regularly as formaldehyde exposure saturates carbon faster.

Why do some filters combine carbon with other materials?

Different materials target different contaminants. HEPA captures particles. Carbon removes gases. Zeolite adsorbs ammonia. Potassium permanganate oxidizes formaldehyde. Combined media filters address broader contamination ranges than single-material filters. This multi-layer approach provides comprehensive air cleaning.

Does humidity affect activated carbon performance?

High humidity reduces activated carbon effectiveness. Water molecules compete for adsorption sites on carbon surfaces. Performance decreases when relative humidity exceeds 70% as water occupies active sites. Dehumidification before carbon filtration improves performance in humid environments.

How much carbon do I need in my air purifier?

Carbon quantity depends on room size and contamination levels. Light odor control needs 1-2 pounds of carbon per 500 square feet. Heavy odors or high VOCs require 3-5 pounds for the same area. Thicker carbon beds provide longer contact time and better adsorption.

Can activated carbon remove all odors?

Activated carbon removes most organic odors from cooking, pets, smoke, and VOCs. It doesn’t eliminate all smells. Some odor molecules have low molecular weight and resist adsorption. Ammonia, hydrogen sulfide, and some amines require specially treated carbon or alternative removal methods.

Breathe easy,

Michael

SOURCES

- Air Science, “Adsorption vs. Absorption: The Difference for Carbon Filters,” February 7, 2022

https://www.airscience.com/adsorption-vs-absorption-the-difference-for-carbon-filters - AirClean Systems, “How Carbon Adsorption Works”

https://aircleansystems.com/news/how-carbon-adsorption-works - Oransi, “Activated Carbon & Carbon Absorption,” June 24, 2021

https://oransi.com/blogs/how-it-works/activated-carbon-activated-carbon-adsorption - Water Professionals, “Activated Carbon Filters”

https://www.waterprofessionals.com/learning-center/activated-carbon-filters/ - General Carbon Corporation, “Activated Carbon Adsorption,” March 21, 2024

https://generalcarbon.com/facts-about-activated-carbon/carbon-adsorption-2/ - EMIS, “Activated carbon adsorption”

https://emis.vito.be/en/bat/tools-overview/sheets/activated-carbon-adsorption - University of Nebraska-Lincoln Extension, “Drinking water treatment: Activated carbon filtration”

https://extensionpubs.unl.edu/publication/g1489/na/html/view